Lab is making Star Trek's transparent armor a reality

It's not precisely transparent aluminum, but NRL's ceramic spinel has the same properties and is a potential game-changer for military and commercial uses.

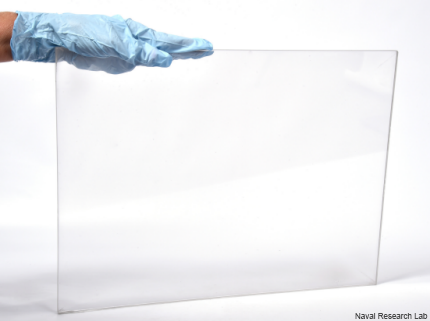

NRL is pressing spinel powder into transparent domes, sheets and other shapes.

In the 1986 movie “Star Trek IV: The Voyage Home,” the Enterprise crew travels back from the 24th century to present-day Earth where, among other things, Scotty barters for enough Plexiglass to build a giant whale tank by offering the formula for “transparent aluminum.”

As it turns out, the movie was not too far off in placing the technology closer to present times, as we may soon be seeing—and seeing through—something similar. The Naval Research Laboratory is developing a version of the gemstone spinel that, rather than being transparent aluminum, is a transparent ceramic that could produce armor-strength windows, as well as make camera lenses and smartphone screens that don’t scratch or break.

And because it’s much stronger than glass, thinner, lighter layers of it would be required for, say, aircraft windows, sensors or any other purpose now performed by glass. "For weight-sensitive platforms—UAVs [unmanned autonomous vehicles], head-mounted face shields—it's a game-changing technology," Dr. Jas Sanghera, NRL’s lead researcher on the project, said in a release.

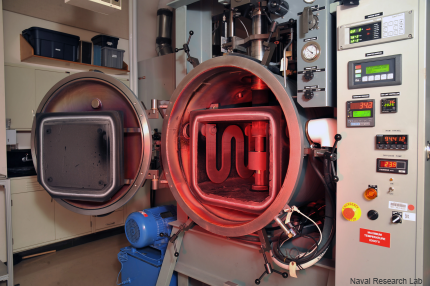

The lab uses a hot press and a process called sintering to create and shape the spinel.

Spinel (pronounced spin-ELL) is magnesium aluminate, a mineral that is produced on a low-temperature hot press and an NRL-invented process called sintering that can shape it to fit the contours of an aircraft, dome or other design, and can be ground and polished in the same way as a gemstone. And because of its material, it also has "unique optical properties,” Sanghera said, “not only can you see through it, but it allows infrared light to go through it," unlike glass, which makes it ideal for military imaging systems.

NRL’s spinel is made up of crystal particles that prevent the kind of cracks that can happen with glass. "It's like navigating through the asteroid belt, you create a tortuous path: If I have all these crystals packed together, the crack gets deflected at the hard crystals: you dissipate the crack energy," he said. And because it can be mined or made synthetically, it’s fairly cheap to produce.

“For weight-sensitive platforms … it's a game-changing technology,” Sanghera says.

Sanghera sees a lot of possibilities for spinel, from rugged consumer electronics to transparent armor and face shields. It could make for thinner bullet-proof glass and be used in protective covering for infrared cameras and satellite sensors. NRL also is considering using it in its next-generation, ceramic laser.

NRL made pieces of transparent spinel in its lab that were 8 inches in diameter, then licensed the technology to a company that produced plates up to 30 inches wide. But the size of a sheet is limited only by the size of a press. "Ultimately, we're going to hand it over to industry," Sanghera said, "so it has to be a scalable process."

The size of the plates is limited only by the size of the press.